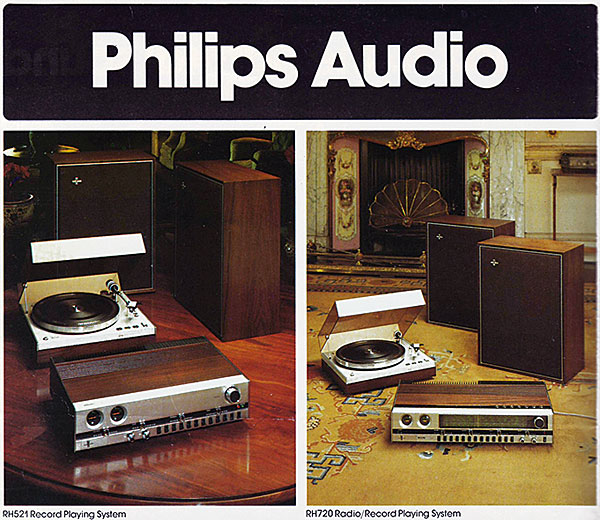

Philips GA 202 Electronic Turntable

This compact '70s deck packed some clever tech when it came to speed control, but is it now an underappreciated classic? Time to find out as the GA 202 is put to the test...

This compact '70s deck packed some clever tech when it came to speed control, but is it now an underappreciated classic? Time to find out as the GA 202 is put to the test...

When designing any turntable, ensuring that it maintains the correct and consistent speed is of paramount importance. Numerous techniques have been tried over the years, some with greater success than others. The Philips GA 202 Electronic turntable reviewed here was one of the first popular models to feature a motor controlled by an electronic servo, bringing easy operation and improved performance. This was the deck's key feature, but there were other striking aspects to the design.

Tacho Belle

The GA 202 first appeared in 1970, which was at a time when almost every other turntable used a substantial AC motor driven directly from the mains supply, its speed locked to the incoming frequency. Various mechanisms involving stepped pulleys and mechanical linkages had been evolved to give a selection of speeds.

Instead of this, the Philips design used a small DC motor of a type similar to that found in a cassette recorder. It had a tacho generator fitted to its shaft so that the speed could be measured electronically. It was therefore possible to construct a feedback servo loop where the motor could be made to run accurately at any speed, automatically compensating for changes in load and temperature. The motor was sufficiently flexible to allow the speed-changing mechanism to be dispensed with altogether, 33.33, 45 and 78rpm being selected electronically.

Fine-speed tuning was also included, with pre-set adjustments for each of the three positions. Another advantage of the electronic motor was that the deck could operate without conversion in both 50Hz and 60Hz markets, something which Philips exploited by selling the GA 202 in the USA under its Norelco brand name.

Clever though this motor was, it did not produce a lot of torque and ran best at speeds faster than are normal for turntable applications. So a two-stage belt drive was used to achieve the necessary reduction, the first stage hidden, along with the tiny motor, in a box inside the plinth. The motor was resiliently mounted inside this box, which was further rubber mounted to the rest of the deck.

Fancy Free

Inside, a short flat belt linked the motor to a shaft that passed upwards to the topside of the GA 202. A further belt took the drive to a resin hub which supported the pressed-steel platter with its bonded rubber mat. The arrangement worked well, but there were drawbacks. The high gear ratio could have caused damage to the belts when the motor was switched off, or confuse the servo system if the speed was changed from a high to a low setting.

The answer was a freewheel mechanism in the drive (perhaps no surprise in a design originating in a country so enamoured with the bicycle!), its location being in the smaller of the two pulleys under the platter. It worked 'steplessly' and allowed the platter to run on, even when the motor was stationary.

The rest of the GA 202 was no less remarkable. It used a suspended subchassis that was formed around a rigid V-shaped assembly hung beneath the top plate on three compliant coil springs onto which the arm base and an unusually deep turntable bearing were fixed. A substantial weight was attached to the front to counterbalance the load of the arm while a spring beneath the platter countered the tension of the belt.

Stop Light

The cueing system on the subchassis was linked to the user control via a tiny Bowden cable (more bicycle technology) for perfect isolation. At a time when automation was the hallmark of a quality turntable it was a surprise to find that the GA 202 was a manual model, albeit with electronic logic controls to start and stop the motor. The only automated function was that the platter stopped at the end of a record, but rather than compromise the arm design with mechanical linkages, the sensing for this was done optically. The system simulated the action of the 'velocity trip' arrangements found in traditional turntables, and was sensitive to the rapid movement of the stylus in the record's run-out groove, not its absolute position.

The arm itself used a slim, straight tube with a counterweight mounted on a compliant insert to damp resonances. Downforce was set by sliding a weighted collar towards the headshell once the arm had been balanced, with rings engraved into the arm at 1g increments.

As for the cartridge, this was fitted to a slide-out assembly inside the headshell, the mountings following the standard pattern. A range of high-quality MM pick-ups was produced in a series known as 'Super M'. The basic GP 400, seen here, was the standard model, with upgrades fitted with elliptical styli available at extra cost.

Touch And Go

The design of the GA 202 was later revised with the introduction of the GA 212, which is arguably the definitive version. This saw the drive system refined to the point where the complex two-belt drive could be dispensed with altogether and replaced with a more conventional arrangement. A small flywheel fitted to the motor pulley ensured smooth operation.

The GA 212's most distinctive feature was its use of touch sensors to select the speed and to start and stop the motor. Either 33.33 or 45rpm was selected by simply touching a small circular pad which then lit up in green to confirm the function was engaged, the 78rpm speed having been deleted. The cueing arrangement gained a beautifully effective silicone fluid damping system that ensured the stylus always landed on the record gently.

The final version, introduced in 1976, was the GA 312. This could be recognised by its black headshell, along with touch sensors lit by red LEDs rather than the green filament bulbs used for the GA 212. Inside the deck, further improvements were made to the servo system in a bid to wring the last drop of performance out of the motor. Meanwhile, a solenoid, which lifted the arm at the end of a record, was also added.

The Philips GA 202 is neat and compact, taking up much less space than many a modern turntable. However, while clearly carefully engineered, some of its parts, such as the bright metal wrap over the central part of the plinth, aren't especially well attached and don't give an impression of quality. Also, the arm feels insubstantial and appears to be the antithesis of today's overtly precision-engineered alternatives.