BSR BDS 80 turntable

A classic belt-drive turntable from a brand that time forgot, but is this fully-automatic, British-built mid '70s deck still worth seeking out? It's time to put it to the test...

A classic belt-drive turntable from a brand that time forgot, but is this fully-automatic, British-built mid '70s deck still worth seeking out? It's time to put it to the test...

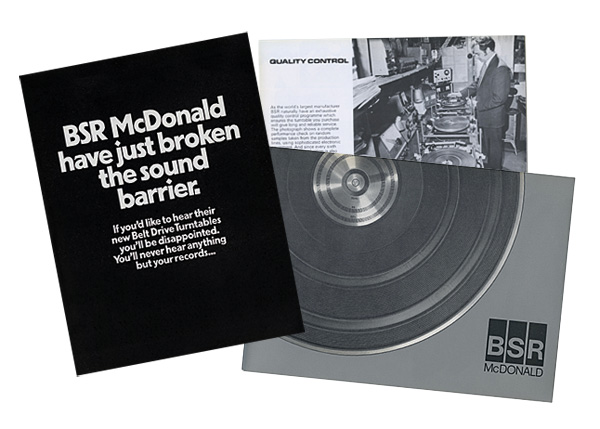

Birmingham Sound Reproducers, or BSR, is a name that's scarcely mentioned in hi-fi circles today. Once the world's largest producer of turntables, the story of this company serves as a reminder of what a tough place the audio market can be.

BSR grew to prominence during the 1950s when the demand for decks, for portables and radiograms reached unprecedented heights. In those days, fully automatic operation and automatic record changing were expected features but no British radio manufacturer was willing to commit the necessary resources to design the complex mechanisms required. BSR's off-the-peg products solved this problem and its Monarch series dominated, firstly at home and then when exported.

Established Design

BSR sold substantial numbers of turntable units to both American and Japanese manufacturers, with the likes of Sony, Matsushita and Hitachi being among the long list of customers. Even Philips, a company that produced automatic turntable designs of its own, included a BSR deck in some of its models.

Although countless variations were offered, most BSR turntables followed an established design formula. The deck's top plate comprised a steel pressing mounted on compliant springs and was housed within the cabinet of the host equipment. A simple AC induction motor with its speed locked to the mains frequency drove the inner rim of the platter via a rubber idler wheel, while speed selection was accomplished by moving the idler to steps of different diameters on the motor shaft. The automatic functions were purely mechanical, although they could follow involved sequences including automatic record size detection and automatic shut-off once the last record had been played.

Stacks Of Fun

The many hidden levers, arms, springs and cams that made this all work were driven by a gear cut into the hub of the platter – hence the necessity of using idler drive to reliably obtain the required torque. Almost all these BSR models featured automatic record change, with the unplayed discs stacked on an extended centre spindle which contained a clever mechanical catch that released them one by one onto a growing stack on the platter below.

A corollary of this was that the centre spindle needed to be both stationary and hollow so the platter bearing was invariably a race of small steel balls that ran between two polished washers.

BSR's position seemed secure until equipment began to arrive in the UK from overseas in quantity. Models such as the Pioneer PL-12D and B&O Beogram 1000V didn't cost much more than BSR's top offerings but they had lightweight arms which could exploit better cartridges, needle point centre bearings that didn't rumble and silent-running belt drives. BSR did its best to compete by introducing its McDonald range (named after company founder, Daniel McLean McDonald) but initially these were mildly revised versions of the standard designs.

The German-made 710 and 810 'Transcription' models were exceptions, but despite their sophistication in some areas they were still idler-driven record changers with the design compromises that entails.

The BDS 80 reviewed here can be seen as a more serious attempt by BSR to move upmarket. BDS stood for 'Belt Drive Series' and this initially comprised two models: the BDS 80 and the BDS 90. Introduced in 1975, they addressed some of the failings of the previous models yet could still be manufactured on BSR's existing tooling.

The BDS 80 was the simpler of the two, the BDS 90 having a more delicate arm supported by a gimbal bearing. The adoption of belt drive was the obvious key selling point, but the designers had not left it at that. Instead of being pressed from steel plate, the 1.8kg platter was cast in alloy and machined to tolerance. A heavy rubber mat was included to help damp any resonances and the motor was synchronous, boasting four poles rather than the usual two. BSR traditionally made four-speed turntables, with 16rpm and 78rpm on offer alongside the more familiar 33.3rpm and 45rpm. As if to demonstrate its hi-fi credentials, the BDS 80 offered the latter two choices only. This was a serious turntable for the serious listener.

A single-play model only, the BDS 80 no longer needed a fixed and hollow centre spindle. Instead, the spindle was stubby and rotated with the record, machined to size with the rest of the platter to ensure accuracy. With the need for the noisy ball-bearing race of the old models now gone, the designers went to great lengths to design a really good replacement.

This took the form of an extended steel boss fitted to the deck's top plate which the platter fitted over. The platter's weight was carried by a single fixed polished ball, set into the top of the boss which provided an ideal point contact. Side loads were handled by phosphor bronze inserts pressed into the bore of the platter hub.

Step Forward

The arm received attention too. It was built around a square section alloy tube and had a dynamic balancing arrangement to set the downforce. A removable slide carrier held the cartridge, with models like the Goldring G800 and Shure M75 being the new lightweight choices to replace the heavy ceramic and crystal pick-ups that BSR used to recommend. The deck was still fully automatic, but included a cueing lever for those who wished to operate it manually.

The styling had also been tidied up, the deck having an attractive matt black top plate with silver trim and a teak veneered plinth. The finished product looked similar to Garrard's SP25 MkIV, though that was still an idler-drive turntable at this stage. While none of this was groundbreaking taken in the context of the industry as a whole, it was a big step forward for BSR.