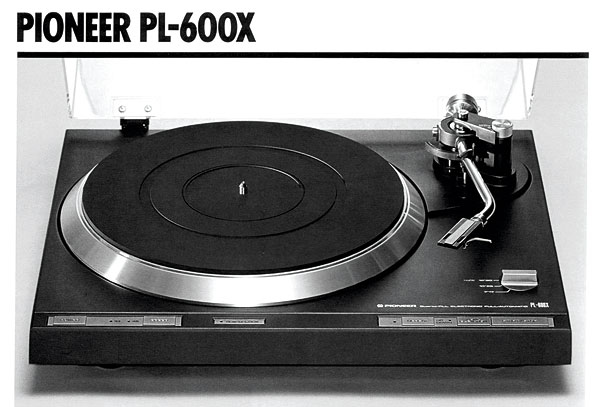

Pioneer PL-600 Turntable

Automatic arm, quartz-locked motor and a chassis that was a challenge to design... How will this one-time, top-tier direct-drive turntable from 1979 shape up today?

Automatic arm, quartz-locked motor and a chassis that was a challenge to design... How will this one-time, top-tier direct-drive turntable from 1979 shape up today?

Every keen LP listener should try to experience the joys of a quality direct-drive turntable in their system at least once. Everyone knows the popular favourites, but in the past all the big Japanese names made one or two decks that should still fit the bill.

Pioneer is perhaps best remembered for its PL-12D entry level belt-drive deck, but this became outdated once direct-drive had trickled its way down from the high-end to appear on mainstream models. There was more to Pioneer than just the PL-12D, however, for the company always offered a full range of turntables to suit a broad spread of budgets and expectations.

Rotor Motor

The PL-600 came from a range of related models offering a series of incremental improvements. For those starting out, the PL-100 offered belt-drive performance, but for around £100 the simplest direct-drive model, the PL-200, could be bought. The next improvement was quartz lock, fitted to the PL-300, then the PL-400 brought fully automatic operation. A bigger, heavier platter and automatic functions powered by an extra small motor were the key benefits of the PL-500 package.

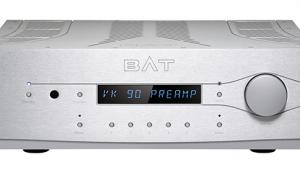

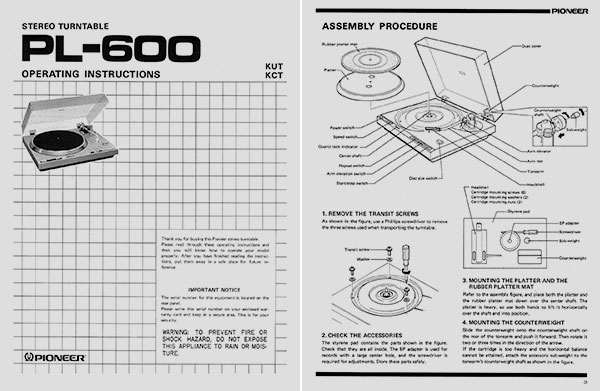

The PL-600 reviewed here was the top model in the series and offered every possible feature and refinement. Platter drive came from the company's Stable Hanging Rotor quartz-locked motor, the platter itself being a substantial and accurately machined aluminium casting. The arm automation was electronically controlled and used optical sensing in order to decouple the automatics from the arm's cartridge-carrying duties. Power cueing was included, with the traditional mechanical lever replaced by a key on the control panel. Unusually for a direct-drive deck, a suspended sub-chassis was used, hung from a die-cast alloy plinth that formed the main body of the player. The arm had a gentle 'S'-shaped twist and was engineered to the highest standards.

Coming Clean

The PL-600, then, was Pioneer's premier conventional turntable for the 1979-1980 season. Those wanting more had to pay £450 for the linear-tracking PL-L1000, which was an expensive option given that a B&O Beogram 4002 [HFN Apr '23] with electronic linear tracking arm and the company's top cartridge cost £100 less.

The key parts of the PL-600 came directly from the previous year's PL-630 model. The motor and arm were essentially the same, but the rather fussy styling of the '630 had been cleaned up to create something more in tune with the 1980s, which were just over the horizon.

Table Torque

Meanwhile, the electronics had been simplified by the use of new integrated circuits that cut the component count without losing functionality. The structure of the PL-600 was similar to that of the Technics SL-Q303 [HFN Jan '18]. The arm unit and spindle motor were rigidly mounted to a pressed steel tray, which formed the turntable's baseplate. This was suspended by a coiled spring under tension in each corner, fitted coaxially with the four feet. These were braced at the top by the large casting, which formed the visible part of the plinth. All the electronics and controls were attached to this plinth, separating them from the arm and platter.

When it came to the SL-Q303, this layout was straightforward to execute as all the parts were reasonably light in weight. But the complete PL-600 tipped the scales at 11kg, 2kg heavier than the PL-500. Much of this mass was in the platter and mat, meaning the motor had to provide plenty of torque to get this combination up to speed and correct it for any changes in loading. Pioneer claimed servo lock from a standing start within a quarter of a turn and stability with up to 200g of drag. This required the suspension to have an unusual degree of horizontal stiffness without this affecting its vertical compliance, a goal achieved by wrapping each spring in a rubber tube with a thin wall.

Other aspects of the design were reasonably conventional. The size selector was a manual knob that looked like the mechanical selector on lesser models. However, inside this was an electronic switch which, in turn, programmed the photo-electric system that controlled the tonearm.

Real Treat

From across the room the PL-600 could be any Japanese direct-drive automatic turntable of the era and doesn't look very different from the sub-£100 plastic cheapies that dominated the market at the time. Up close, though, its considerable size becomes more apparent, as does the quality of the materials and finish. The majority of the parts that you see and touch are metal and the arm has clearly been engineered to a very high standard. Some versions came with Pioneer's PC-200 MM cartridge, but the standard mounting and headshell mean that any high-quality alternative may be fitted – ours came with a suitably period Audio-Technica/Signet TK-7E.

Once switched on, the PL-600 can be used as a manual player. This sees the platter begin to spin when the arm is lifted from the rest and stop again when the arm is replaced. This works well, but the electronically controlled automatics are the real treat. Most automatic turntables use gears driven from the platter spindle to move the arm, but to show this isn't the case with the PL-600, the arm lifts and begins to move before the platter starts. The motion is silky smooth and almost noiseless, in my view beaten only by the far more complex Sony PS-B80 [HFN Jul '12].

Dead Ringer

The power cueing is also super-slick and a delight to use. Big, heavy platters can take quite some time to come to rest, but not the PL-600's, which employs an electronic brake to bring the record to a prompt stop. The platter rings like a bell if struck without the mat in place but is completely 'dead' with it fitted, showing that even this apparently simple part of the package has been designed with skill and care. There is little here to offend the most critical student of electronic or mechanical engineering, which in my experience is rare when it comes to turntables.