Improving Groove Contact Page 2

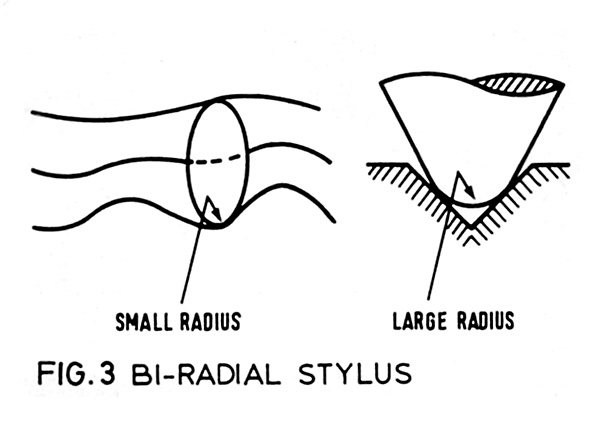

In the case of the elliptical tip the contact area is extended in the vertical direction by merging the small side radius (5µ) into a relatively large major radius (18µ), the latter approximating to that normally used on a spherical tip (0.7mil). This, coupled to lower moving masses at the tip, reduces the load on the disc grooves and reduces record wear.

New Tip Design

In the case of the latest types of stylus tip, which include the Shure Hyperelliptical, the Shibata and the Pramanik, this vertical contact is elongated still further by using even larger effective radii for the vertical plane of the contact surface. But now, Goldring has taken the idea one stage further by adopting a new tip design for its G900/IGC cartridge. The tip originated from Aalt Jouk van den Hul, and the letters IGC stand for 'intimate groove contact'.

Having examined the other tip designs available van den Hul became convinced that there were two common misconceptions about these designs. The first was that production versions exactly followed the geometry of the original design and were of a high standard of finish. The second was that the contact area of the latest designs remained constant.

A theoretical study showed the latter to be far from true and that, for example, at high frequencies the point of contact would rotate around the minor radius (viewed in plan) and could vary considerably in size. Secondly, he was able to demonstrate that due to the manufacturing techniques adopted to obtain the multiple radii on many of the later designs, production quality suffered, resulting in a distortion of the designer's original shape, or in poor mounting of the tip on the cantilever. In a presentation by Mr van den Hul at the Spring High Fidelity Show, he made the following points, quoted from his speech:

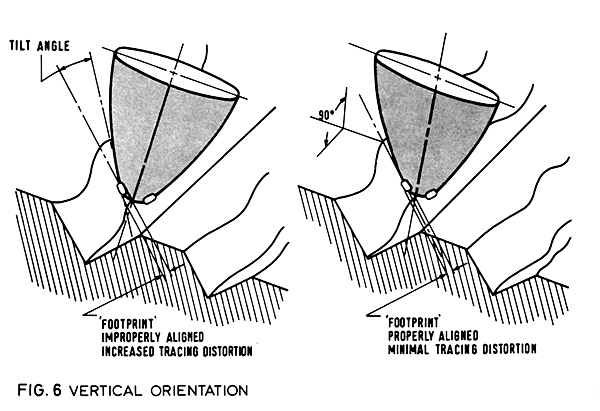

'Due to the vertical orientation of the original disc cutter, the modulation in all record grooves has a vertical orientation. [Not to be confused with the direction of 'vertical' motion, which is not truly vertical for other reasons.] The replay tip should also retain this exact orientation. Where there are deviations, tracing is not correct and fails to have a defined direction [see Fig 4]. For example, the Shibata displays a poor tracking line because of the combination of a basic conical shape with additional planes, producing a 3D curve which does not have an exactly vertical contact line. One can also examine the rounding of the tip in the plan view, where the radius may not be constant. This parameter affects harmonic distortion...

'Because of the small contact radius of the new tip, only a very small part of the groove is traced. The positive aspect of the new tip shape is that the tip movement exactly follows the groove modulation. Tracing of these frequencies is impossible with larger and more crudely shaped tips. Therefore many cartridge manufacturers were forced to "build in" a cantilever resonance to produce a higher output at high frequencies to flatten the overall output frequency curve. This also produces loss of definition...

'In the case of multi-radial tips, the contact "islands" move round the tip as the stylus traces a modulation wave in the wall. This can produce incorrect tracing, and intermodulation distortion results [and also Doppler distortion].'

Back To The Grind

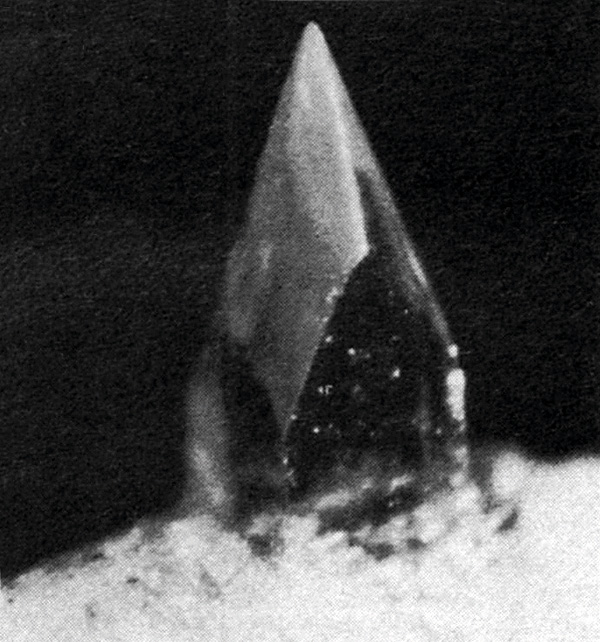

So exactly what are the design features of the van den Hul tip? In appearance, it has a very slim wedge-shaped profile [see Fig 5] having an unusually long contact line formed by adopting a vertical plane major radius of about 80 microns. Because the leading and trailing surfaces are formed from two large-radius conical shapes, the contact radius in plan view is a constant over a large part of the tip and is close to four microns.

Van den Hul points out that the tip is formed from a carefully selected square section rod of diamond oriented so that the contact radii are formed from the side walls, which are harder. The use of the square shank also ensures considerable accuracy in the alignment of the tip with relation to the cantilever. This is a fault that he maintains is common to many other tips, especially where a round section rod is used.

Finally, the van den Hul stylus is produced by specially devised grinding and polishing techniques that have raised the consistency of geometry, from sample to sample, to a level not previously obtained in tip manufacture.

Van den Hul claims that by going back to examine the original design of the cutter and then using as much as possible from this source in designing the new tip, he has produced a more optimal stylus than anything previously available. Also, by paying attention to the problems of surface finishing and mounting, he can offer greater consistency in the geometry of the tip when mounted in the cantilever. The particular geometry used produces an exactly vertical contact line, with no curvature, while the small contact radius ensures any effects from rotation of the contact point when tracing groove modulations of short wavelength are minimised.

Disc Quality

The claims will have to be tested by review, but the Goldring cartridge does appear to offer advantages over other designs aiming for the same objectives. However, in attempting to approach the shape of the cutter more closely (without producing a cutting blade) van den Hul may have overlooked the possibility that maintenance of cutting styli is not always as good as it should be, so the groove could have a less than ideal shape. His tip might be less tolerant of such situations. Nevertheless, this should not be an argument for diluting the design of the replay tip, but emphasises the need to improve disc quality at all stages of production.