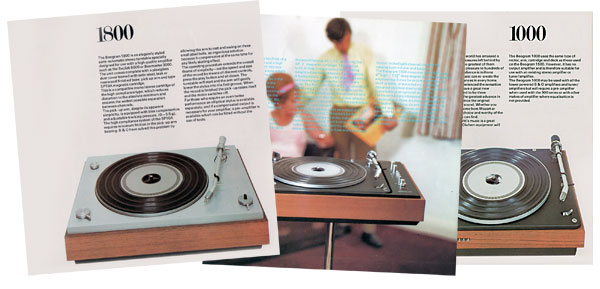

B&O Beogram 1800 turntable

Designed to be worthy of the company's flagship Beolab 5000 system, this late '60s turntable was the last conventional deck to top the B&O range. How does it sound?

Designed to be worthy of the company's flagship Beolab 5000 system, this late '60s turntable was the last conventional deck to top the B&O range. How does it sound?

The argument for building a system using components from different manufacturers because 'no company is good at everything' is a good one – up to a point. Conversely, the Japanese heavyweights such as Sony, Technics and JVC were once able to put together a fairly convincing complete package, as could Philips (on a good day!).

However, B&O was the real specialist when it came to the 'all under one roof' philosophy, reinforced by the stylistic integrity of its components and the occasional use of slightly odd interconnection standards. This is not to dismiss the company's technical prowess. After all, it holds an enviable list of records, world firsts and key patents in a wide range of domestic audio technologies.

Key Problem

The company's Beolab 5000 system of 1968 [HFN Dec '13, and see p18] caused a problem when it came to system building. The sudden step up in quality represented by both the Beolab 5000 amplifier and Beomaster 5000 tuner meant that the firm's Beogram 1000 turntable was no longer good enough to perform the vital role of key source component.

Initially the issue was addressed by offering a Beocord open-reel tape recorder with the system, but its high cost and a lack of pre-recorded material meant that this was not a practical solution. As a stop-gap, Thorens TD124 motor units fitted with B&O arms and cartridges were released, this concoction being known as the Beogram 3000. The real answer, of course, was for the company to design its own high-quality turntable.

The Beogram 1000 had its origins in the late 1950s and, despite numerous detail changes, it was still recognisably the same machine with which B&O had entered the stereo era. Compact and completely manual in operation, the 1000 had been so popular in the UK that B&O advised its dealers only to sell them to customers buying other B&O equipment since production could not keep pace with demand. The Beogram 1800 seen here could be viewed as a 'Super Beogram 1000', although beyond the motor and speed-changing mechanism the two shared few parts in common.

Silver Side Up

The Beogram 1800 featured a number of improvements that made it a completely up-to-date turntable. It had a floating sub-chassis built onto a solid plinth, the latter available in teak, rosewood or white finishes. A new arm design was employed, which could exploit B&O's new high-compliance cartridges, and new mechanisms beneath the surface brought automatic starting for any size of disc and automatic cut at the end of the record. Meanwhile, the rather dowdy appearance of the 1000 was addressed with a recessed platter, an elegant silver top plate and a striking new lid framed in brushed alloy.

As one might expect from B&O, the highest standards of engineering were employed throughout. The plinth was made from stout wooden sections for maximum rigidity and these supported a heavy alloy die-casting that formed the top plate of the deck. The bottom side of this had formed into it all the mounting points necessary to hold the rest of the 1800's working parts while the top was polished and lacquered to give an attractive finish.

The new arm was built around a straight aluminium tube and employed dynamic balancing to set the tracking force. An ingenious system of ball bearings running on an inclined track smoothed the arm's radial movement while at the same time providing anti-skating compensation.

Platter 'N' Pads

The SP12 cartridge at the tip of the arm looked very similar to the previous version but could track at less than 2g. B&O's favoured moving-iron principle was retained and this saw a tiny metal cross at the end of the cantilever suspended within four longitudinal coils inside the pick-up's tiny capsule.

Meanwhile, the Beogram 1800's platter looked like that used for the 1000, but it was larger, heavier and designed to minimise resonances. It ran on a hardened needle point and was stabilised radially by a knife edge ring located at the top of the bearing housing to achieve the lowest possible level of rumble. The motor and drive mechanism were retained from the Beogram 1000, although there was no longer a provision for 78rpm records. An initial idler-wheel stage was used to select the speed, then a round-section belt was used to transmit the drive to the platter. The whole assembly was hung from a platform isolated using springs to prevent the transmission of the motor's vibrations.

To allow the speed to be fine tuned, a centrifugal governor was fitted to the motor shaft. This used bob weights mounted on beryllium copper springs to bring an alloy brake disc into contact with a pair of felt pads once the correct speed had been reached. The position of these pads was set by a knob accessible on the top of the deck. As well as giving a good range of adjustment, this system imparted a degree of servo action which maintained a constant speed over a range of loading.

Hidden Preamp

Since not all amps in the late '60s could accommodate a magnetic cartridge a slot was fitted underneath where an equalising preamp (type GF4) could be installed.

The Beogram 1800 was a reasonable sales success but soon became outmoded by changes elsewhere in the B&O range. The Beolab 5000 system was replaced by the smaller, neater Beomaster 3000 receiver whose refined styling did not really suit the square-rigged appearance of the 1800. Much of the mechanism was reworked to become the slimline Beogram 1200, one of the prettiest turntable designs of the 1970s.

However, the minds of B&O's engineers were already elsewhere. In their view, the development of the conventional turntable was already at an end and further improvements would require something radically different. The fruits of their thinking emerged soon afterwards as the tangential-tracking Beogram 4000 [HFN Jun '14], making the 1800 the last completely new conventionally engineered audiophile turntable to top the B&O range.

Semi Automatic

For those used to the low, slim look of B&O products the Beogram 1800 will come as a surprise. It is a big, slab-sided block of a thing, although it is hard to deny that it is elegant (especially in white). With the lid off – there are no hinges – it looks more like a traditional turntable, albeit one where much greater attention than usual has been paid to the choices of materials and the detailed appearance of things like the tonearm and the controls.

Against this the rubber platter mat looks somewhat out of place, but it is worth noting that this was the last B&O turntable design to use one. The Beogram 1800 is a semi-automatic design, meaning that speed and record size must be set manually. This is achieved via the two small levers located on the front of the plinth, but after that all one has to do is to press the black button in the middle of the right hand lever and off it goes.